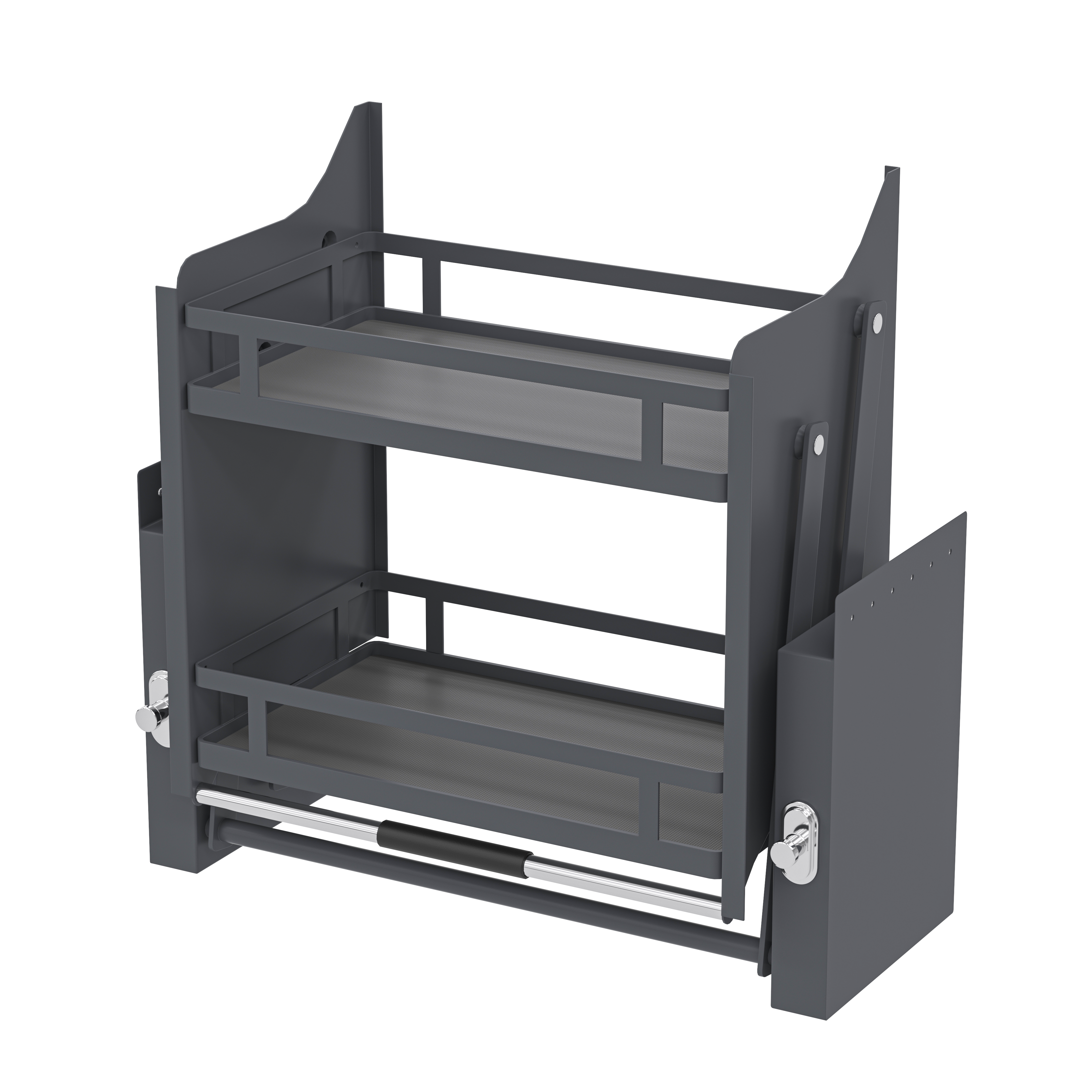

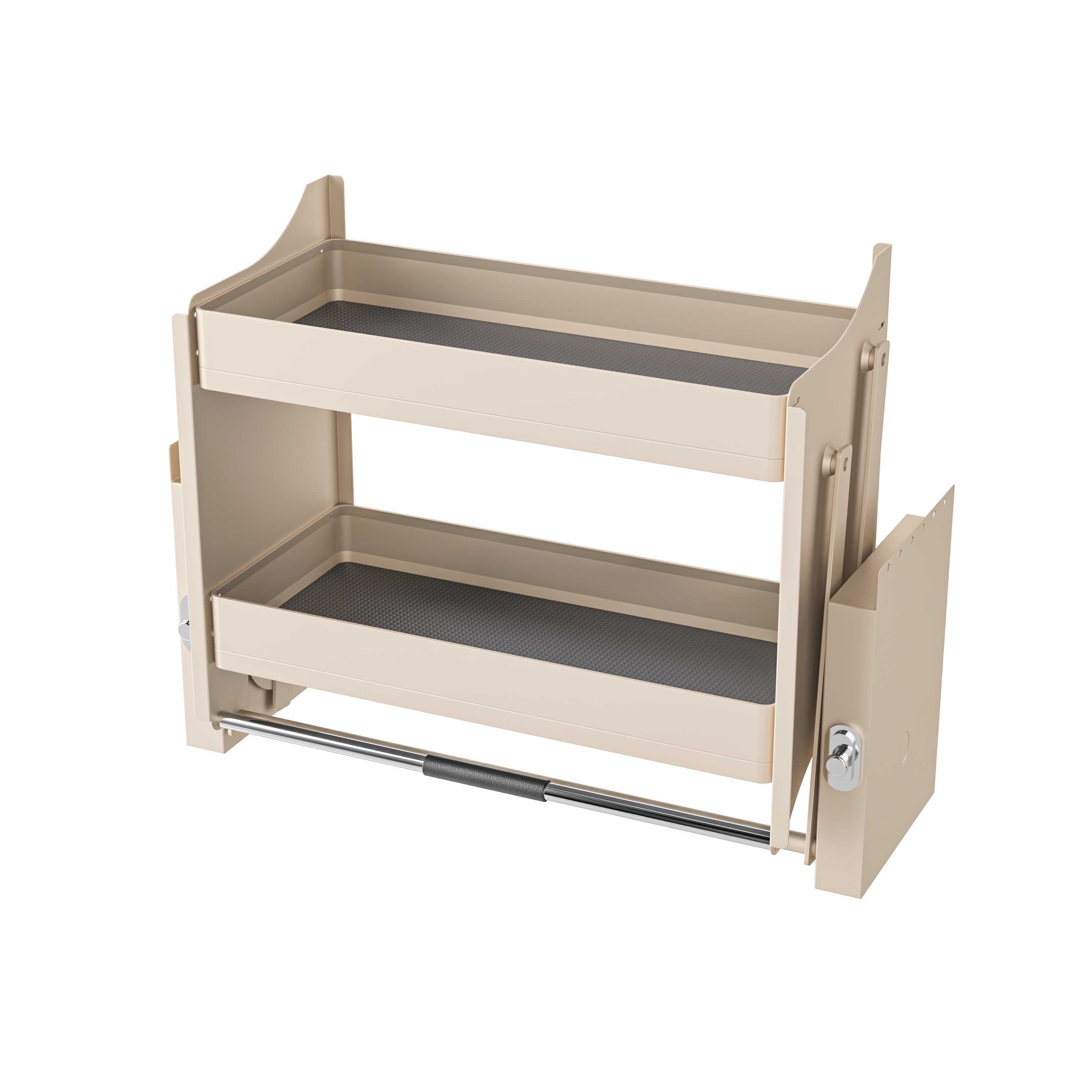

kitchen lift basket manufacturer

A kitchen lift basket manufacturer specializes in designing and producing innovative storage solutions that revolutionize kitchen organization and accessibility. These manufacturers combine cutting-edge engineering with practical functionality to create lift systems that seamlessly integrate into modern kitchen cabinetry. Their products feature precision-engineered mechanisms that enable smooth vertical movement, allowing users to easily access items stored in upper cabinets. The manufacturing process incorporates high-grade materials such as stainless steel and reinforced plastics, ensuring durability and longevity. Advanced production techniques include computer-aided design and quality control systems that maintain consistent product excellence. The manufacturers typically offer various models to accommodate different cabinet sizes and weight capacities, ranging from light-duty organizers to heavy-duty pantry systems. Their products often include safety features such as soft-close mechanisms and load-balancing technology to prevent accidents and ensure stable operation. These manufacturers also prioritize ergonomic design principles, creating products that reduce physical strain and make kitchen storage more accessible for users of all abilities. The production facilities maintain strict quality standards and often hold international certifications for manufacturing excellence.