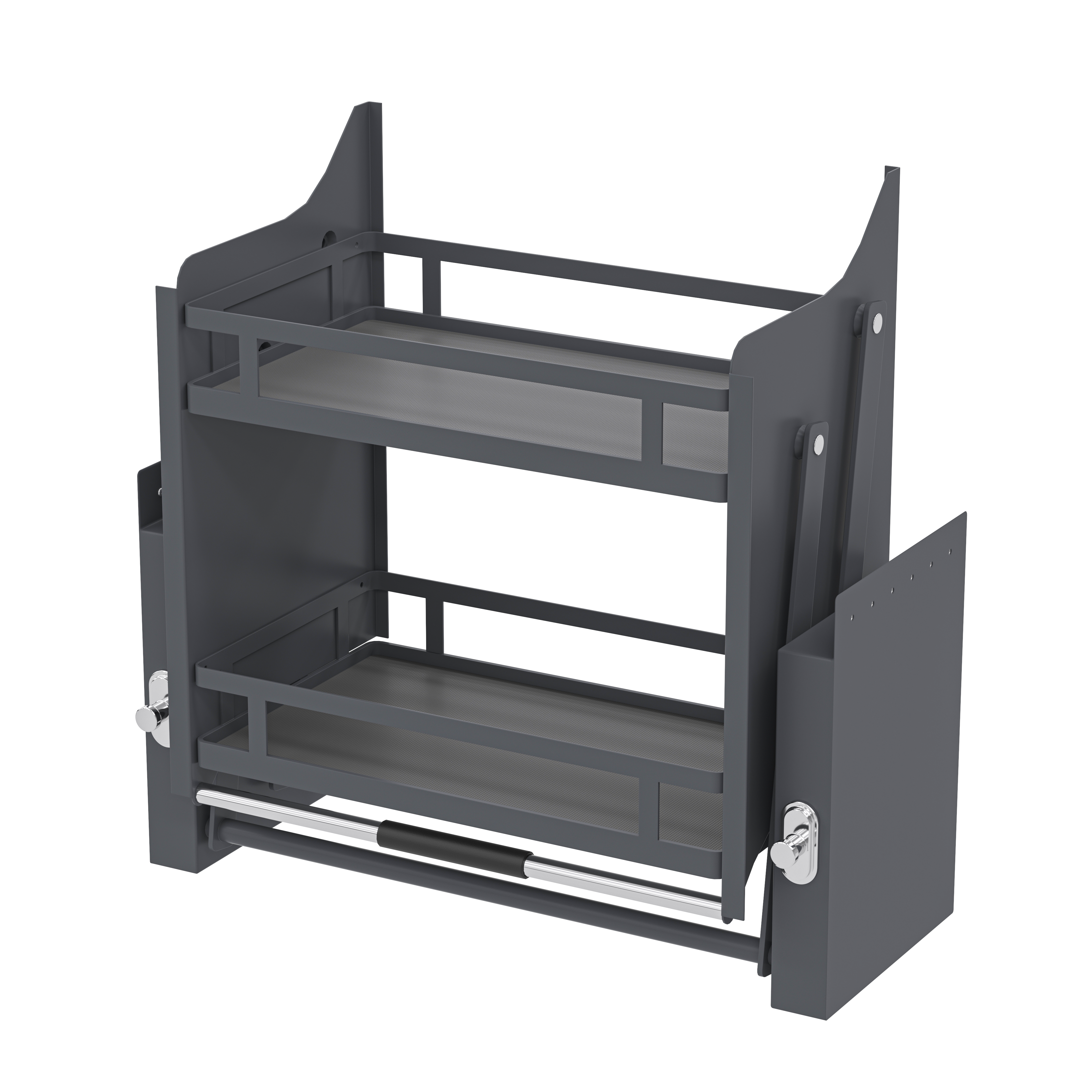

lazy susan corner cabinet organizer manufacturer

As a leading lazy susan corner cabinet organizer manufacturer, we specialize in developing innovative storage solutions that maximize kitchen space utilization. Our manufacturing facility combines advanced automation technology with precise quality control systems to produce durable, smooth-rotating organizers that transform awkward corner cabinets into highly functional storage spaces. We utilize premium-grade materials, including reinforced polymer platforms and precision-engineered bearing systems, ensuring long-lasting performance and reliability. Our manufacturing process incorporates state-of-the-art injection molding techniques and automated assembly lines, maintaining consistent product quality while meeting high-volume production demands. The facility is equipped with advanced testing stations that verify each unit's rotation smoothness, weight capacity, and structural integrity. We offer customization options in various sizes and configurations, accommodating different cabinet dimensions and customer preferences. Our research and development team continuously works on improving design elements, such as noise reduction mechanisms and enhanced weight distribution systems, setting new industry standards for corner cabinet organization solutions.