magic corner manufacturer

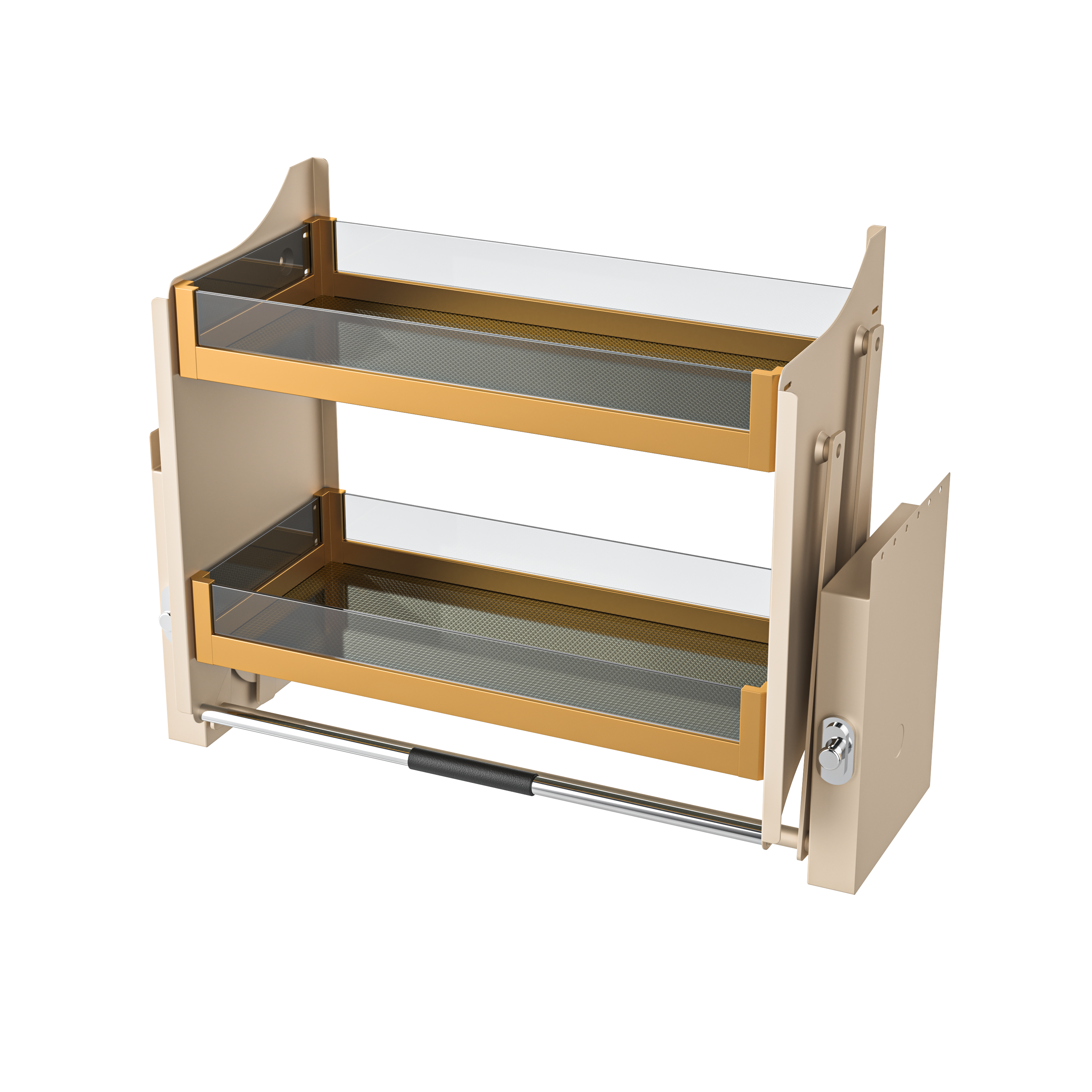

A magic corner manufacturer specializes in producing innovative storage solutions for kitchen cabinets, particularly focusing on maximizing corner space utilization. These manufacturers employ advanced engineering and design principles to create mechanisms that transform traditionally hard-to-reach corner cabinets into accessible storage spaces. The production process involves precision manufacturing of components including sliding rails, mounting brackets, pull-out mechanisms, and storage baskets. Using high-grade materials such as stainless steel and durable plastics, these manufacturers ensure their products meet international quality standards and safety regulations. The manufacturing facilities typically feature state-of-the-art CNC machines, automated assembly lines, and rigorous quality control systems to maintain consistent product excellence. They also incorporate ergonomic design principles to ensure smooth operation and user-friendly functionality. Many manufacturers offer customization options to accommodate various cabinet sizes and configurations, making their products adaptable to different kitchen layouts. The production process includes thorough testing of weight capacity, durability, and movement mechanisms to ensure long-term reliability. Modern magic corner manufacturers also focus on sustainable production practices and eco-friendly materials selection, responding to growing environmental consciousness in the market.