Installing pull down shelves transforms your kitchen storage from frustrating reach-and-strain scenarios into effortless access solutions. These innovative storage systems bring upper cabinet contents within comfortable reach, making cooking preparation safer and more efficient. Whether you're dealing with aging joints, shorter stature, or simply want to maximize your kitchen's accessibility, pull down shelves offer a practical upgrade that enhances both functionality and safety in your cooking space.

Understanding Pull Down Shelf Mechanisms

Basic Operating Principles

Pull down shelves operate on spring-assisted mechanisms that counterbalance the weight of stored items. The system typically includes gas struts or spring assemblies that provide controlled descent and ascent motion. When you pull the handle downward, the mechanism engages smoothly, bringing the entire shelf unit to a comfortable working height. This design ensures that even fully loaded shelves remain easy to operate without excessive force or sudden movements.

The counterbalance system is calibrated to handle specific weight ranges, typically supporting between 15 to 35 pounds depending on the model. High-quality pull down shelves feature adjustable tension settings, allowing you to fine-tune the mechanism based on your typical storage loads. Understanding these weight limitations helps ensure proper installation and prevents premature wear on the mechanical components.

Component Identification

A complete pull down shelf system consists of several key components that work together seamlessly. The mounting brackets attach securely to your cabinet frame, providing the foundation for the entire mechanism. The shelf platform itself features raised edges or wire construction to prevent items from sliding off during operation. The handle mechanism connects to the spring assembly through reinforced cables or rigid linkages.

Additional components include safety stops that prevent over-extension, mounting hardware specifically designed for cabinet installation, and adjustment mechanisms for customizing the operating feel. Some advanced pull down shelves incorporate soft-close features that prevent slamming and reduce noise during operation. Familiarizing yourself with these components before installation helps streamline the process and ensures proper assembly.

Pre-Installation Planning and Measurements

Cabinet Assessment Requirements

Before installing pull down shelves, conduct a thorough assessment of your existing cabinet structure. Measure the interior dimensions carefully, noting the width, depth, and height of the space where you plan to install the system. Check for any obstructions such as plumbing lines, electrical wiring, or existing shelf supports that might interfere with the installation process.

Examine the cabinet construction to determine the material and thickness of the side panels and top. Most pull down shelves require solid wood or plywood construction for secure mounting, as particle board may not provide adequate support for the mechanical stresses involved. If your cabinets feature face frames, measure their dimensions as they may affect the installation approach and hardware selection.

Tools and Materials Preparation

Gathering the proper tools before beginning installation saves time and ensures professional results. Essential tools include a drill with various bit sizes, a level for ensuring proper alignment, measuring tape for accurate positioning, and a screwdriver set for assembly work. A stud finder helps locate solid mounting points in the cabinet structure, while a pencil allows for precise marking of mounting locations.

Additional materials may include wood screws appropriate for your cabinet construction, wall anchors if mounting to hollow areas, and potentially reinforcement blocks for added support. Some installations benefit from having wood glue, sandpaper for smoothing rough edges, and touch-up paint or stain to match your existing cabinet finish. Having these materials readily available prevents interruptions during the installation process.

Step-by-Step Installation Process

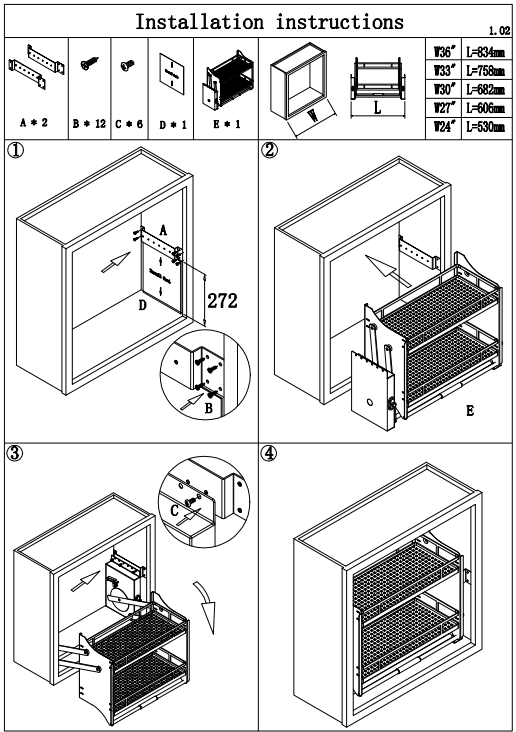

Mounting Bracket Installation

Begin the installation by positioning the mounting brackets according to the manufacturer's specifications. Use your level to ensure the brackets align perfectly horizontal, as any misalignment will cause binding or uneven operation of the pull down shelves. Mark the screw holes with a pencil, then drill pilot holes to prevent splitting the wood during screw installation.

Secure the brackets using appropriate screws, typically 2.5 to 3 inches long for solid wood construction. Tighten the screws firmly but avoid over-tightening, which can strip the threads or crack the cabinet material. Test the bracket stability by applying gentle pressure in various directions to ensure solid mounting before proceeding with the mechanism installation.

Mechanism Assembly and Adjustment

Install the spring mechanism according to the manufacturer's instructions, paying careful attention to the orientation and connection points. The pull down shelves mechanism should engage smoothly with the mounting brackets, creating a secure connection that allows for proper operation. Check that all pivot points move freely without binding or excessive resistance.

Adjust the tension settings if your model includes this feature, starting with the manufacturer's recommended settings and fine-tuning based on your typical storage loads. Test the mechanism operation several times to ensure smooth function before attaching the shelf platform. This preliminary testing helps identify any issues that are easier to address before completing the installation.

Testing and Fine-Tuning Performance

Initial Operation Verification

After completing the mechanical installation, conduct thorough testing of your pull down shelves to verify proper operation. Start with an empty shelf to check the basic mechanism function, ensuring smooth descent and ascent without binding or jerky movements. The shelf should stop securely at both the fully extended and retracted positions without drifting or settling.

Gradually add weight to the shelf platform, testing operation at various load levels up to the manufacturer's specified maximum. Pay attention to any changes in the operating feel or unusual noises that might indicate adjustment needs. The mechanism should maintain smooth operation regardless of the load within its design parameters, providing consistent performance for daily use.

Safety and Stability Checks

Perform comprehensive safety checks to ensure your pull down shelves installation meets all operational requirements. Verify that the safety stops engage properly to prevent over-extension, which could damage the mechanism or cause stored items to fall. Test the stability of loaded shelves in various positions, ensuring they remain secure even when partially extended.

Check all mounting hardware for tightness and proper engagement, as vibration during initial use may cause some loosening. Examine the cabinet structure around the mounting points for any signs of stress or movement that might indicate inadequate support. Address any concerns immediately to prevent progressive damage or safety hazards.

Maintenance and Long-Term Care

Regular Maintenance Procedures

Maintaining your pull down shelves ensures years of reliable operation and preserves the investment in your kitchen storage upgrade. Establish a regular cleaning routine that includes wiping down all surfaces with appropriate cleaners, paying special attention to the mechanism housing where dust and grease can accumulate. Clean the shelf platforms regularly to prevent buildup that could add unnecessary weight or create hygiene issues.

Lubricate moving parts according to the manufacturer's recommendations, typically every six to twelve months depending on usage frequency. Use only recommended lubricants to avoid damaging seals or causing contamination issues in food storage areas. During maintenance, inspect all connections and hardware for signs of wear or loosening that might require attention.

Troubleshooting Common Issues

Understanding common pull down shelves problems helps maintain optimal performance and extend system life. If operation becomes jerky or difficult, check for obstructions in the mechanism path and verify that weight limits haven't been exceeded. Binding issues often result from misalignment or debris accumulation in pivot points, requiring cleaning and possibly readjustment.

Noise during operation typically indicates the need for lubrication or the presence of worn components. Address these issues promptly to prevent progressive damage that could require more extensive repairs. Keep spare parts available for common wear items, and maintain contact information for technical support if complex issues arise.

FAQ

What weight capacity should I expect from pull down shelves

Most residential pull down shelves support between 15 to 35 pounds, with heavy-duty models handling up to 50 pounds. The exact capacity depends on the mechanism quality, mounting method, and cabinet construction. Always verify the manufacturer's specifications and avoid exceeding stated limits to ensure safe operation and prevent premature wear. Consider your typical storage items when selecting a system, accounting for the combined weight of dishes, appliances, or food items you plan to store.

Can pull down shelves be installed in any cabinet

Pull down shelves require adequate interior dimensions and solid mounting surfaces for proper installation. Minimum clearance requirements vary by model but typically need at least 12 inches of depth and 16 inches of width. The cabinet must have sufficient structural integrity to support the mechanism and loaded shelf weight. Face-frame cabinets may require additional mounting considerations, while frameless European-style cabinets often provide easier installation options.

How difficult is the installation process for DIY homeowners

Installing pull down shelves falls within the intermediate DIY skill level, requiring basic carpentry knowledge and standard household tools. Most homeowners can complete installation in 2-4 hours with careful preparation and attention to instructions. The key challenges involve accurate measurement, proper alignment, and understanding the mechanical adjustment procedures. Consider professional installation if you're uncomfortable with cabinet modifications or lack experience with mechanical assemblies.

What maintenance do pull down shelves require over time

Regular maintenance includes cleaning surfaces monthly, lubricating moving parts every 6-12 months, and periodically checking hardware tightness. The spring mechanisms typically last 5-10 years with normal use, while shelf platforms may last indefinitely with proper care. Most maintenance tasks require only basic household tools and common lubricants. Establishing a simple maintenance routine prevents most operational issues and extends system life significantly.